Table of Contents

In this article, we’d like to talk about a question. Why do robot actuators need to be thin?

Lately, a strong wave of automation has been sweeping across the globe. From manufacturing to healthcare, logistics and even aerospace, robotic systems and automated equipment are being adopted at a rapid pace in a wide range of industries. At the center of this trend is a small but essential component called the actuator.

This tiny part plays a big role. It is what makes robots move and perform tasks, just like muscles and joints in our own bodies.

According to market research firm Stratistics MRC, the global market for robot and automation actuators is expected to reach around 24.4 billion dollars in 2024 and grow to approximately 54.8 billion dollars by 2030. An average annual growth rate of 14.4 percent clearly shows just how quickly industrial automation is spreading.

Robot actuators drive major moving parts like arms and joints. They are used in everything from heavy machinery and industrial equipment to robotic arms in hospital operating rooms. They are a key component in enabling precise movement, and when choosing an actuator, factors like accuracy, safety and drive performance all need to be considered together.

1. Three Key Factors When Choosing an Actuator

When selecting a robot actuators, you can’t just go by its size or shape. The conditions it will operate in and the role it needs to play make a big difference in what should be prioritized. Among many factors, three are especially important. These are accuracy, durability and drive efficiency.

Let’s start with accuracy. This often relates to something called backlash. Backlash means the tiny gap between gears inside a reducer, which causes a slight delay or looseness when the rotation direction changes. The smaller the backlash, the lower the positioning error. That is why in fields like semiconductor equipment or surgical robots, where even the slightest deviation is unacceptable, ultra-precise actuators that allow for accurate positioning are essential.

Of course, not every industry requires that level of precision. In sectors like logistics or construction, equipment such as AGVs or lift systems often place more importance on durability than on minimal backlash. These machines are expected to lift and carry heavy loads repeatedly. Because of that, actuators must be built strong enough to withstand long-term use and provide enough torque. We touched on this in a previous article titled “Why is demand growing for high-weight transport in unmanned carrier robots (AGVs)” so if you’re interested, be sure to take a look.

Drive efficiency is another important factor. Even when using the same motor output, the system’s overall performance depends on how much energy is lost inside. What matters is how efficiently that input energy is converted into actual mechanical motion. The less friction and structural loss there is, the more efficient the drive becomes.

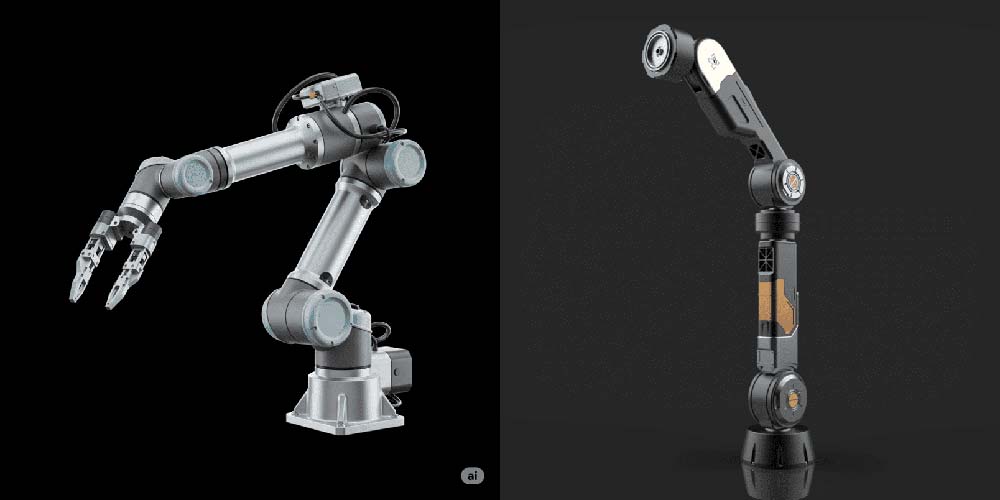

So how does a thin actuator relate to everything we’ve discussed so far? When actuators become thinner, it becomes much easier to reduce the overall size of the robot or make better use of internal space. This opens up far more possibilities when it comes to product design.

Take a multi-jointed robotic arm as an example. Each joint typically houses a combination of a reducer, motor and control unit, all of which together form an actuator. These components are usually arranged in a straight line. This setup ends up creating joints that are long and thick. The limitation of this design is quite clear. As the joints get bulkier, the entire robotic arm needs to be shaped with more bends and angles. That makes it harder to design a smooth and natural curve, like the motion of a human arm.

This kind of structure becomes especially problematic in settings where the robot needs to work in close proximity to people or operate in tight spaces with precision. Imagine a collaborative robot working right next to a human. If the joints take up too much space, it increases the risk of physical collisions and may also make the human operator feel uneasy. On top of that, when the arm has to twist and turn in a complicated way, its working range becomes limited, and it takes longer for it to reach the position it needs.

But what happens if we use an actuator that has a built-in reducer and motor in a thin, integrated structure? In that case, both the length and thickness of the joint can be significantly reduced. This allows for a much sleeker and more unified robotic arm design. Each joint can be more straight and compact, which helps simplify the overall shape of the robot. In this sense, the thickness of an actuator isn’t just about size. It directly affects design flexibility, range of motion and even the safety of human-robot collaboration.

2. The Secret Behind Thin and Powerful Design: Inside the Reducer

To make robot actuators thinner and more compact, the internal design of the reducer becomes extremely important. A reducer is a component that slows down the high-speed rotation of a motor and turns it into stronger torque. How this reducer is structured has a direct impact on the product’s performance, functionality and design flexibility.

Let’s take the commonly used planetary gear reducer as an example. This type of reducer transfers power through a structure where several planetary gears rotate around a central gear. While it provides high torque, it also requires multiple gear stages to achieve higher reduction ratios. That means the gears have to be stacked, making the overall thickness longer. This becomes a clear limitation when trying to build a small and slim actuator.

On the other hand, a cycloidal reducer works differently. When the eccentric shaft connected to the input rotates, the cycloidal disc rolls along pins placed around the outer edge to transmit power. Because the motion is based on rolling contact, friction is minimized. More importantly, this design allows for a wide range of reduction ratios to be achieved in a single stage, even within the same overall size. That makes it easier to secure strong output torque without increasing the thickness of the unit.

Thanks to these structural advantages, the cycloidal reducer makes it possible to build actuators that are thin but still powerful. The ability to implement various reduction ratios in a one-stage system within a fixed size is especially useful for robotic systems where space is limited.

Of course, as the reduction ratio increases, rotational speed naturally goes down. But in environments where strong torque and lightweight design matter more than speed, this trade-off actually works in favor of the application. For example, in lift equipment used on construction sites where stable lifting power is essential, it is a clear advantage to achieve both high torque and high reduction in a compact, slim form. This unique combination of slim design and strong output is one of the key benefits that only a cycloidal reducer can offer.

3. The Benefits of a Slim Actuator Structure in Robots

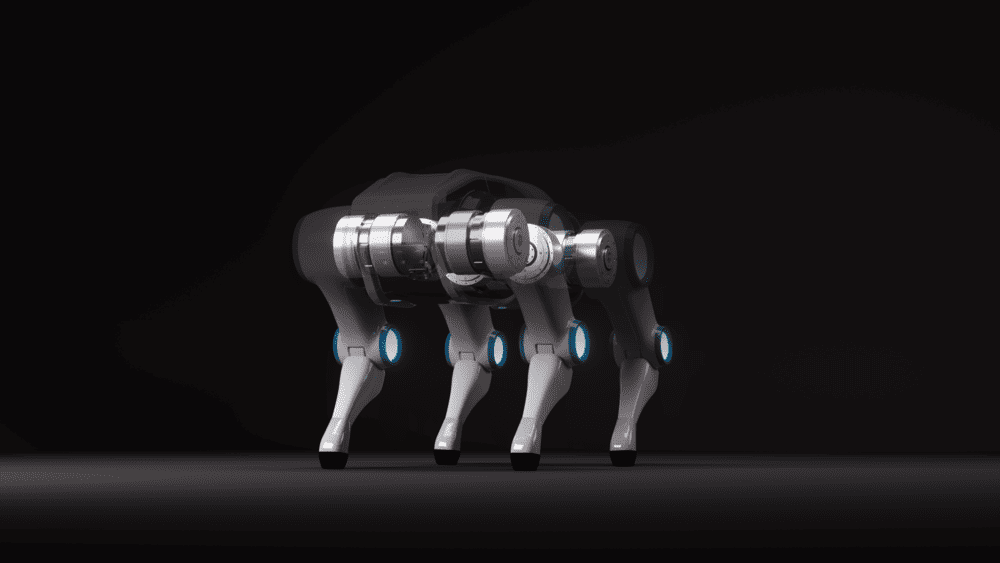

When an actuator becomes thinner, it brings a wide range of benefits to overall robot design. The first and most noticeable advantage is greater design flexibility. If the actuator is thick, the joint sections become bulky, and the entire shape of the robot tends to be fixed in a more rigid form. In contrast, using a slim actuator allows for narrower joints and a more flexible overall structure. This is especially useful when designing humanoid robots that need to perform complex movements or mimic the human form. The thinner the actuator, the easier it is to replicate narrow and intricate areas like human arms, legs or wrists.

Another important benefit is the reduction of moment of inertia. When weight is positioned farther from the center, it takes more energy to rotate and the movement becomes slower. But if the actuator is thin and the mass is concentrated closer to the center, the robot responds more quickly and with better agility. This matters a lot in humanoid robots where multiple joints need to move rapidly and naturally. It helps achieve smooth and lifelike motion, much like a human.

There is also the added benefit of reduced interference between components. Slim actuators make it possible to place joints closer together, which means the robot’s arms or legs can move with fewer collisions or interruptions from nearby parts. This makes it easier to carry out complex motion paths and contributes to a more humanlike and refined outer appearance.

The advantages in terms of weight reduction are also clear. In humanoid robots, long limbs and numerous joints mean that the weight of each individual component significantly affects the robot’s overall balance and energy consumption. When actuators become thinner and lighter, the robot’s total load decreases and more room becomes available for batteries. This ultimately leads to improvements in system efficiency, operating time and overall stability.

Designing actuators with a thinner profile does more than just reduce bulk. It enhances motion performance, strengthens design competitiveness and contributes to overall weight savings. For robots like humanoids that are meant to resemble the human form, this kind of slim structure is not just an option but often a critical design requirement.

In fact, Tesla’s humanoid robot Optimus is equipped with more than 28 high-output servo actuators. Including the tiny linear actuators used in its fingers, the actual number is even higher. In a humanoid structure where each joint requires its own actuator, the thickness and weight of those actuators play a decisive role in the overall design.

Across the United States, China and even here in Korea, the race to develop humanoid robots is growing increasingly competitive. In this field, a single robot may contain 40 to 50 actuators on average, and in some cases, nearly 100. When dozens of actuators must be built into one machine, reducing their size and weight becomes a key factor that directly affects the robot’s overall performance.

4. Application Examples

So how are thin and compact robot actuators actually being used in real systems? Let’s take a look at two specific fields to see how this structural approach provides clear advantages in design.

4-1. Collaborative Robots

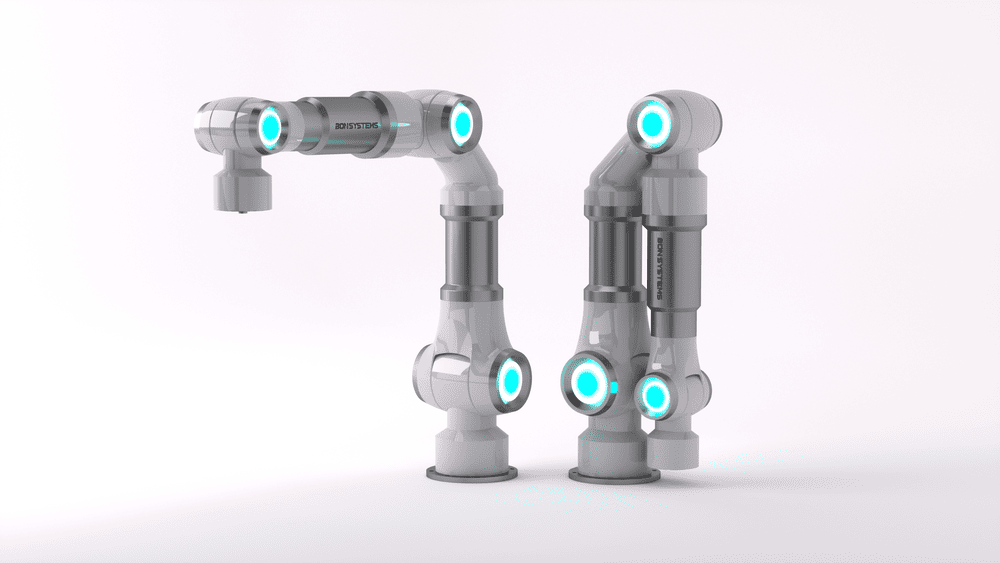

Traditional collaborative robots typically featured a design where a reducer and motor were arranged in series at each joint. As a result, the robot arms naturally had to be designed with a bent or angled shape. However, as actuators have become thinner and capable of adopting a dual-end support structure internally, it has become possible to design robot arms that are closer to a straight-line form.

This change is not only about appearance. A slim, linear actuator structure allows for a reduction in overall volume and brings new flexibility to how the robot is configured. By moving away from bent, bulky shapes toward a slimmer straight profile, designers gain more freedom in managing total weight, center of mass and component layout. It opens up a broader range of choices for building more efficient and balanced robots.

4-2. Logistics Robots

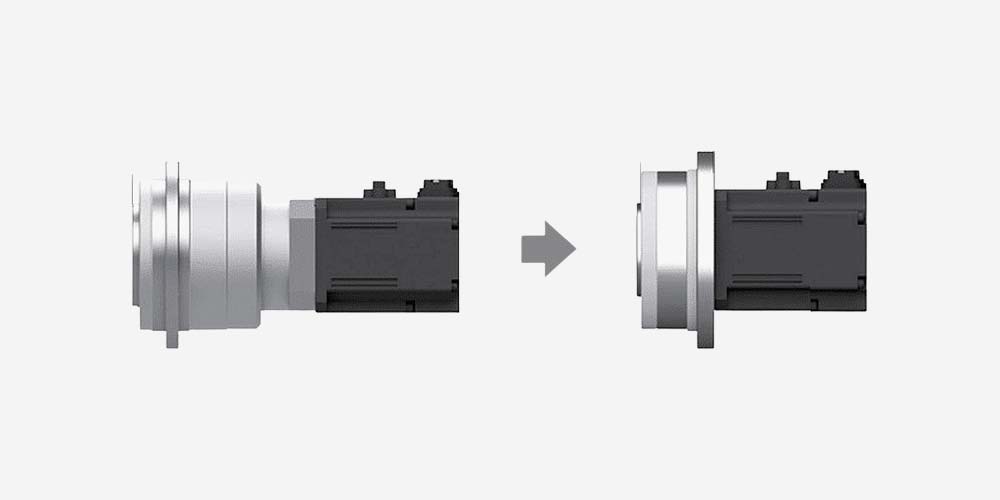

In the initial design of one client’s AGV (Autonomous Guided Vehicle), a standard geared motor-based actuator was used. We proposed a redesign using a cycloidal reducer, and as a result, we successfully reduced the total actuator length by approximately 70 percent.

This improvement made a significant difference. By dramatically shortening the length of the actuator, we were able to simplify the internal layout of the overall system. When an actuator becomes more compact, it gives engineers greater flexibility in positioning other components and helps reduce the overall complexity of the design. In the field of logistics robotics, where miniaturization and modularity are key, this kind of compact configuration can serve as a strong design alternative.

(For more on this AGV reducer improvement case, see our article “Why We Offer Custom Reducer Design Services.”)

5. When You Make It Thinner, the Robot Changes

For a long time, most robot actuators have followed a familiar structure. Motors and reducers are placed in a straight line, delivering torque and control in a simple and straightforward way. While this approach is easy to implement, it has always come with limitations in terms of space efficiency.

At Bon Systems, we chose to focus on this very challenge. Our goal is to keep the same output performance while reducing size and simplifying the structure. This isn’t just about making parts smaller. It’s about opening up more design freedom for the entire robot. It means better space for wiring, improved weight distribution and even more room for batteries.

This is especially important in humanoid robots, where a humanlike form is the goal. The thinner the actuator at each joint, the more freedom the robot has to move and expand its range of capabilities. That’s exactly why we specialize in cycloidal-based actuators designed with a slim profile.

Of course, making actuators smaller is not easy. It involves solving one technical challenge after another. But we continue to face those challenges every day and turn them into progress.

If you’re interested in learning more about our products or exploring the right actuator configuration for your own robot system, feel free to contact us. For a more accurate consultation, it helps to share details about the intended application and specific technical requirements.

For example, output torque, precision level, motor RPM, available mounting space and environmental constraints are all useful information. If you already know the quantity or delivery schedule you have in mind, please let us know. It will help us review your case more effectively.

Big possibilities can fit inside a compact structure. Let’s explore that potential together with Bon Systems.

Frequently Asked Questions (FAQ)

Q1. Why do robot actuators need to be thin?

A thinner actuator helps reduce the overall size of the robot and allows more efficient use of internal space, making it easier to achieve a cleaner and more functional design. This is especially important in multi-joint robotic arms, where reducing the size of each joint section can significantly improve design flexibility and motion efficiency.

Q2. Doesn’t reducing the thickness of an actuator weaken the torque?

Thanks to the structure of the cycloidal reducer, it is possible to deliver strong torque even in a slim form. With a single-stage design that supports a wide range of reduction ratios, necessary torque can be achieved without increasing the overall size of the actuator.

Q3. How does a cycloidal reducer work?

When the eccentric shaft connected to the input rotates, the cycloidal disc rolls along pins placed around the outer edge to transmit power. This rolling motion reduces friction and enables smooth power delivery.

Q4. What types of robots benefit the most from thin actuators?

Humanoid robots, which have many joints in tight spaces, rely heavily on actuator size and weight. In such systems, a thin and lightweight actuator plays a critical role and becomes a key factor in the overall design.

Q5. What information should I prepare for an actuator consultation?

To provide the most accurate support, please share details such as the application area, required specifications (like output torque, precision, motor RPM), space limitations, environmental conditions, quantity needed and your preferred delivery schedule. The more we know, the better and faster we can assist you.

※ References

Global Information | Robotics and Automation Actuators Market Forecasts to 2030 – Global Analysis By Type, Actuation, Payload Capacity, Application, End User and By Geography (January 1, 2025)

Bonsystems Global | There’s a reason we make robot actuators thinner (May 24, 2025)

WIKIPEDIA | Epicyclic gearing (April 7, 2025)