Table of Contents

Why Did Investors Bet 5 Billion KRW on Bon Systems?

Robots are becoming more and more humanlike. Their movements are growing increasingly precise, and the way they operate feels remarkably natural. But what kind of technology makes such intricate and refined motion possible? The answer lies in the core of it all: the drive system. At Bon Systems, we develop and manufacture reducers and actuators based on cycloidal gear technology. Recently, we secured a 5 billion KRW investment, backed by the strength of this very technology. For us, this isn’t just about raising capital. It is a meaningful milestone that validates both our technological capabilities and our potential for growth in the robotics market. In this article, we would like to share why Bon Systems is drawing attention from investors and how our unique technical strengths are shaping the future of motion.

BCSA: A New Standard for Actuators

The robotics industry is expanding at a remarkable pace. While industrial robots that perform repetitive tasks in factories once dominated the landscape, today their applications span far more diverse fields, including healthcare, logistics, aerospace, and service robotics. As robots take on increasingly complex roles in a wider range of environments, the key technical requirement is becoming clearer. It is all about how naturally a robot can move. To carry out various tasks with stability and precision, advanced motion control technology is essential. In fact, one could argue that a robot’s overall performance hinges on how accurately it can control its movement.

At the core of that motion lies the actuator. The actuator is the component that enables a robot to move, applying force and controlling position and posture. In human terms, it functions much like a joint. The way a robot moves and the range of motion it can achieve are directly influenced by the configuration and performance of its actuators. In short, actuators are a defining element in both design and capability.

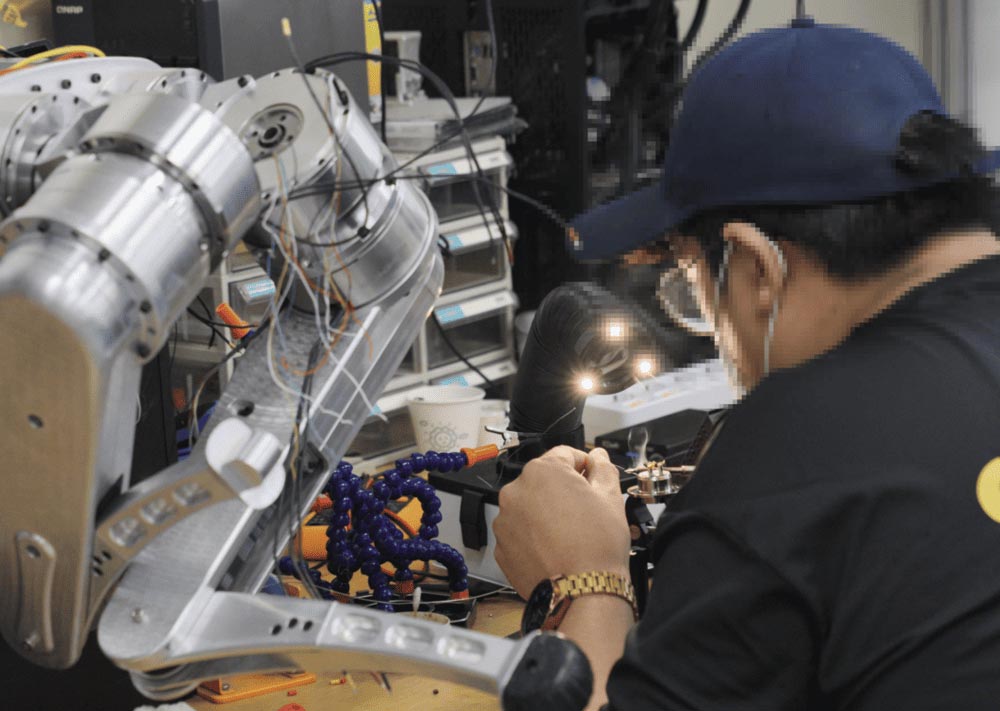

At Bon Systems, we have spent years developing actuators with a focus on balancing structural constraints and performance. Our result is the BCSA (Bon Systems Cycloidal Smart Actuator), an integrated unit that combines a reducer, motor, encoder, and driver into a single compact system. Unlike the traditional method of assembling these components separately, BCSA is designed as a unified structure from the outset, solving multiple challenges at once.

This integration shortens the total length and allows for slimmer joints. It simplifies the assembly process and reduces the risk of interference between components. In robots with multiple joints or those operating in space-constrained environments, structural efficiency is critical. BCSA is well-suited to meet these demands.

But the advantages of BCSA go beyond structure. It also addresses key performance requirements. For instance, backlash the slight lag caused by gaps between gears when changing rotation direction can significantly affect a robot’s position control precision. In applications like surgical robots or semiconductor handling systems, where fine movements are required, minimizing backlash is absolutely essential.

On the other hand, in industries like logistics, manufacturing, or construction, a different set of priorities comes into play. High output torque, durability, and structural rigidity that can withstand repetitive vibration and shock become critical. Without meeting these conditions, equipment performance may degrade rapidly over time.

Because each industry presents different demands, selecting an actuator cannot be based on output power or size alone. Backlash, structural stiffness, durability, and gear ratios must all be considered in combination to ensure optimal performance for each specific environment.

Why Actuator Thickness Matters

In robot design, the thickness of actuators has a greater impact than it may initially seem. This is especially true for multi-joint robotic arms, where several joints are connected in series. When the reducer, motor, and control unit are configured separately and aligned in sequence, the joint section naturally becomes longer and bulkier. As a result, the robot’s range of motion becomes limited, and design flexibility decreases.

These limitations become even more pronounced in collaborative robots that work close to humans or operate in tight, confined spaces. If the joints are large and bulky, the robot’s overall appearance becomes awkward. In collaborative environments, this not only increases the risk of physical collisions but can also create psychological discomfort for human coworkers.

BCSA was developed to address these challenges from the very beginning, with a design philosophy focused on thinness and compact integration. By combining the reducer, motor, encoder, and driver into a single unit, BCSA achieves a slim profile without sacrificing output torque. (You can learn more about this in the article titled “The Evolution of Robot Joints: Smart Actuators“)

Thin actuators do more than just save space. They contribute to various improvements such as robot appearance, design flexibility, ease of assembly, and safety in human-robot interaction. In other words, actuator thickness is a crucial factor that influences the entire robot design.

Take AGVs (Automated Guided Vehicles), for example. When actuators occupy less space, it opens up room inside the body. This allows for larger battery capacity or more flexible arrangements of control units. With optimized structures, in-wheel type designs where the drive system is housed directly within the wheel become realistically achievable.

Similarly, in humanoid robots where appearance and proportions matter, reducing joint thickness makes it easier to replicate human-like silhouettes. This is not just a matter of aesthetics. In scenarios where robots work in close proximity to people, such designs help reduce psychological barriers and enhance user-friendly experiences.

The Result of Years of Research: Cycloidal Gear Technology

To develop actuators with a slim profile, the internal reducer plays a critically important role. At Bon Systems, we have consistently focused on the structural advantages of cycloidal gear technology and have committed ourselves to its advancement through ongoing research and development. Cycloidal reducers transmit rotational force through a rolling motion rather than sliding contact. This results in reduced friction, enhanced durability, and the ability to support a wide range of gear ratios within the same external dimensions. These qualities make it a highly adaptable solution for compact and efficient designs.

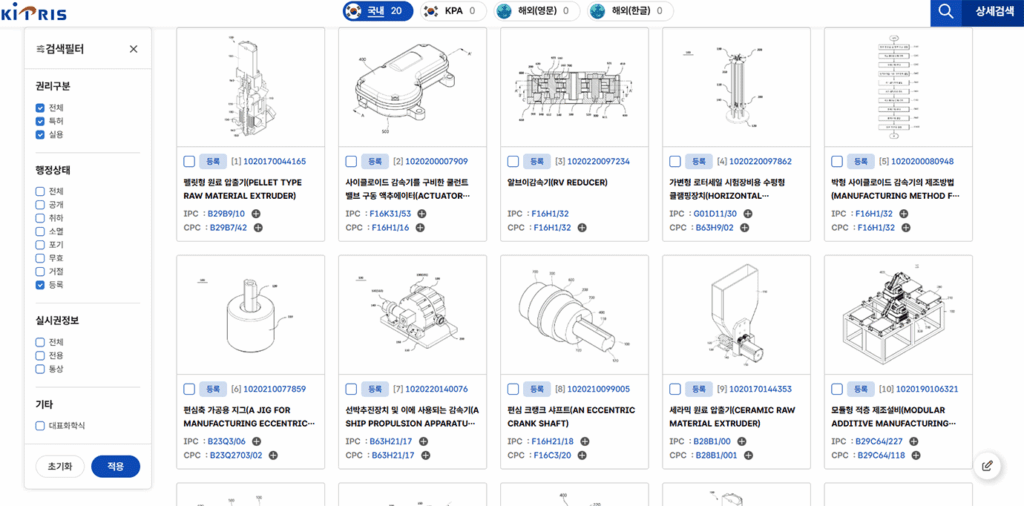

Our approach goes far beyond simply applying existing technology. Throughout the entire product development cycle, we have built original expertise that reflects our deep understanding of this field. Our innovations include roller-bearing-based reducer architecture, ultra-thin cycloidal reducer design and manufacturing techniques, optimized eccentric shaft geometry, structural enhancements for improved heat dissipation, and mechanisms to prevent internal gear backlash. Many of these innovations are covered by patents, and they directly contribute to the enhanced reliability and performance of our actuators.

What truly sets Bon Systems apart is our ability to design and optimize all of these components entirely in-house. We do not rely on external technologies. This level of self-reliance demonstrates our technical independence and underscores the unique competitiveness that defines our position in the market.

Moving Beyond Component-Driven Design

Until now, robot design has often followed a pattern where the structure is shaped around pre-existing components. Instead of selecting parts that best suit a specific design goal, engineers have had to adjust their designs to fit standardized components already available on the market. In many cases, this approach has led to unnecessary constraints and inevitable compromises in performance.

At Bon Systems, we set out to overcome these structural limitations through technology. We have developed our own reducers and actuators that can be flexibly adjusted in terms of gear ratio, torque, backlash, backdrive characteristics, and external form. These components are offered as customized configurations, tailored to meet the specific needs of each client project.

This approach brings significant advantages. It not only expands the freedom of design but also creates real improvements in overall system performance, energy efficiency, and spatial optimization. Instead of adapting to the limitations of standard components, engineers can now design products that align more closely with their original goals. Bon Systems is proud to be part of this shift, helping to create an environment where design leads and technology follows with flexibility.

After the Investment: What Comes Next for Bon Systems?

Following the successful investment round, Bon Systems is entering a new phase. We are evolving beyond being a technology-focused company and are taking concrete steps toward becoming a manufacturing business with reliable and scalable production capabilities. While our past efforts centered on designing and building custom components based on specific client needs, we are now shifting toward establishing a mass production system for standardized product lines.

To support this transition, we are actively investing in automated production infrastructure. Our aim is to simultaneously achieve three key goals: faster delivery times, improved cost competitiveness, and consistent product quality. As this system becomes fully operational, Bon Systems will strengthen its position not only in the domestic market but also as a trusted supplier for global clients who value a balance of lead time, quality, and price.

We are also preparing for our listing on the KONEX market in 2025, with plans to move to KOSDAQ between 2026 and 2027. As part of this roadmap, we are continuing to expand investment in humanoid robot technology, deepen our core technologies, and broaden our product portfolio. This recent funding is more than a short-term capital injection. It serves as a strategic foundation for enhancing our company value and accelerating entry into the global market.

(Source: Newsis | “Bon Systems Plans KONEX Listing to Become a Robot Hardware Platform Leader,” June 11, 2025)

Looking ahead, Bon Systems remains committed to developing motion technologies that make robots stronger, more precise, smaller, and more adaptable. We will continue to serve as a reliable partner, offering both rapid, custom solutions and scalable standard products. Together with our clients, we aim to set new benchmarks at the center of change.

FAQ

Q1. What makes BCSA different from conventional actuators?

A. BCSA (Bon systems Cycloidal Smart Actuator) is an all-in-one actuator that integrates a reducer, motor, encoder, and driver into a single unit. Unlike traditional systems where these four components are assembled separately, BCSA is designed as a compact and slim structure from the beginning. This integrated approach simplifies assembly and significantly enhances design flexibility for robotic systems.

Q2. Why does Bon Systems focus on cycloidal reducers?

A. Cycloidal reducers transmit rotational force through a rolling motion, which minimizes friction and enhances durability. They can also provide various gear ratios within the same external dimensions, offering excellent design flexibility. Bon Systems has continuously refined this structure with a focus on thin-profile design and high torque output. This ongoing development has become the foundation for the distinct performance advantages of our products in real-world industrial applications.

Q3. Do you offer custom actuator solutions?

A. Yes, we do. Bon Systems has the engineering and manufacturing capabilities to flexibly adjust specifications such as gear ratio, output torque, backlash, backdrive characteristics, and external dimensions. We help clients move beyond the limitations of standard components by providing actuators tailored to meet specific design goals.

Q4. Which industries are BCSA actuators suitable for?

A. BCSA can be applied to a wide range of sectors including collaborative robots, AGVs, AMRs, humanoid robots, and construction robotics. It is especially effective in environments that require high torque, compact form factors, or precise motion control. Its advantages include design flexibility, durability, and ease of integration.

Q5. What are Bon Systems’ future business plans?

A. We are currently transitioning from custom-only manufacturing to mass production of standardized product lines. Our plan includes building automated production infrastructure to simultaneously achieve faster delivery, better cost competitiveness, and consistent quality. Looking ahead, we aim to list on the KOSDAQ by 2027 while continuing to advance our core technologies and expand our product portfolio.