Table of Contents

Building a humanoid robot might seem like something only major research labs or global tech companies would attempt. But at Bonsystems, our journey began with something that was simple in idea and surprisingly complex in practice: the hand.

In this blog post, we’ll share how we started our humanoid robot project by developing a 5-degree-of-freedom robotic hand. If you’re interested in how to build a robot for beginners or want to build a robotic hand for your own project, this hands-on story will give you a practical starting point along with valuable lessons we learned throughout the process.

Why We’re Building a Robotic Hand

Bonsystems is a South Korea–based engineering company that specializes in high-torque, compact actuators and cycloidal reducers. For years, we have developed motion components used in AGVs, quadruped robots, and automation systems.

So why would a company known primarily for hardware components start building robots?

The reason is simple. We wanted to demonstrate what our components can actually do in motion. Rather than showing technical specs on paper, we wanted to show real-world movement using our own actuators and reducers. After building mobile robots, we felt ready to tackle the next challenge. a humanoid robot.

To begin that journey, we needed to start small but meaningful. We chose to build a robotic hand first, because it’s not only one of the most technically complex parts of the body but also a perfect testing ground for compact, high-torque actuators.

Why Start with the Hand?

If you’re wondering how to build a robot for beginners, starting with the hand might seem a bit overwhelming. But there’s a clear reason we chose to begin here.

The human hand is capable of far more than simply grabbing objects. It can thread a needle, balance a spoon, use chopsticks, or gently lift a fragile egg without breaking it. These actions demand high levels of precision, responsiveness, and most importantly, the ability to control force with subtle variation. This makes the hand one of the most challenging environments for testing actuators and sensors.

For a robotic hand to replicate even a small portion of these movements, it must have multiple degrees of freedom, compact actuators, and real-time feedback. This combination made the robotic hand the perfect platform to validate the performance of the hardware we develop.

Why Start with the Hand?

If you’re wondering how to build a robot for beginners, starting with a robotic hand might sound intimidating. But there’s a clear reason we chose to begin here.

The human hand is capable of far more than just grasping. It can thread a needle, hold chopsticks, or gently lift an egg without breaking it. These actions require precision, real-time responsiveness, and subtle force control. exactly the kind of challenges that push actuators and sensors to their limits.

For a robot to perform even part of these actions, it needs multiple degrees of freedom, compact and reliable actuators, and responsive feedback systems. That’s why we decided to build a robotic hand first. It gave us the best environment to test what our motion technology is really capable of.

Designing the 5DOF Robotic Hand

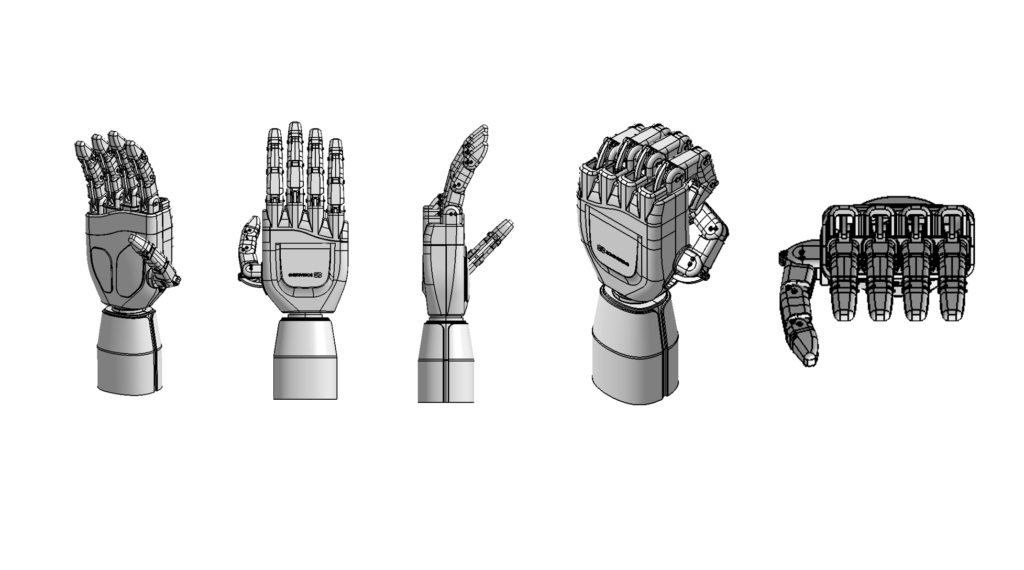

We started with a 5DOF linkage-type hand design. Our approach wasn’t about achieving perfection from the start, but about building iteratively. solve one issue, move on to the next. This let us focus on mechanics and motion rather than polish.

For the first prototype, we used gear motors that were too large to fit into a realistic hand. The result was an oversized robotic hand, but that was fine for testing. Each finger was made of multiple segments, connected with pins and snap rings instead of bolts, which kept the profile clean but added assembly complexity.

We used SLA 3D printing for the housing. It was fast, low-cost, and easy to modify. ideal for prototyping. However, post-print shrinkage meant we had to rework parts for bolt clearances and surface flatness.

If you try to build a robotic hand yourself, you’ll likely find that most off-the-shelf actuators fall short. Ours lacked the torque, compactness, and durability needed for lifelike movement over time. That’s why we’re now developing our own miniature actuator based on a patented cycloidal gear system. optimized for small robotic joints with high torque demands.

Once our control logic is complete, we’ll release version two of the hand, now featuring our in-house actuator. This will result in a smaller, more realistic design with much better performance.

How to Build a Robot for Beginners: What We Learned

For those wondering how to build a robot for beginners, here are some practical lessons from our robotic hand project.

- Start small but relevant. Don’t aim for a full humanoid immediately. Choose a functional part, like the hand, and focus on making it work.

- Don’t wait for perfection. Build a working prototype, then iterate and improve.

- Document everything. Capture design files, videos, and even your mistakes. This makes troubleshooting easier later.

- Focus on functionality first. Beautiful design means little if the joint can’t move reliably.

- Allow time for sensors. Force sensors, encoders, or tactile feedback will take time to tune.

- Choose or create the right components. In our case, that meant developing a custom actuator to meet our motion and torque goals.

- If you’re planning to build a robotic hand or any moving robotic part, these tips will save you time and frustration.

Watch the Build in Action

We’re sharing every step of this project on our YouTube channel. If you’re interested in how to build a robotic hand or want to follow the full progress of our humanoid robot project, make sure to subscribe to our YouTube channel and sign up for the newsletter on our website.

FAQ

Q: Why is Bonsystems building a robot?

We want to demonstrate the real-world performance of our actuator and reducer technologies. Building actual robots is the most effective way to do that.

Q: Why did you start with the hand?

The hand is a compact but complex structure that demands precise control and torque. It’s the ideal way to test our high-torque actuator systems.

Q: When will the humanoid robot be ready?

We aim to present the full version at RoboWorld 2025.

Q: Can you build a robot for my company?

Yes. We offer custom-designed robotic hardware and actuator solutions. Please contact us with your specific requirements.

Q: Can I collaborate with this project?

Absolutely. We welcome collaboration with developers, control engineers, and research partners interested in robotics.