Autonomous driving robots are rapidly becoming central to modern industrial environments. They are no longer just machines that follow pre programmed routes they have evolved into systems that can perceive their surroundings and make decisions independently based on the context of the workspace. Equipped with sensors, artificial intelligence (AI), and control systems, these robots can operate without human commands, interpreting their environment and autonomously carrying out assigned tasks.

This transformation has been made possible by the integration of AI and machine learning technologies into robotic systems. In particular, recent advances have introduced natural language interfaces, significantly changing how robots are trained. Without the need for complex coding or manual programming, robots are now reaching a level where they can learn through conversational instructions, much like a human would.

Autonomous driving robots are being applied not only in manufacturing but also across logistics, agriculture, and service sectors. They are gaining strong attention, especially in workplaces struggling with labor shortages, where automation is becoming a practical and scalable alternative.

In this article, we explore what autonomous driving robots are, why they are becoming essential now, where and how they are being used, and how the technology is expected to evolve in the near future.

1. What Is an Autonomous Driving Robot?

The core of this technology lies not in movement, but in judgment. An autonomous driving robot is fundamentally a system designed to sense its environment, analyze situations, and take action based on purpose without any direct control. The term “autonomous” itself implies that decision making takes place within the robot, which is one of its defining characteristics.

In the past, robots simply repeated pre programmed tasks. Today, however, they are capable of adapting their behavior when conditions change. For instance, if a robot is navigating a warehouse and unexpectedly encounters an obstacle or a human worker, it no longer just stops. Instead, it assesses the new situation, recalculates an alternative path, and continues toward its destination. Achieving this level of response requires a combination of sensors, control systems, and AI driven data processing.

What matters is not movement alone, but the system of judgment and execution that enables movement. These robots decide when to stop, where to go, and how to most efficiently reach a goal by constantly analyzing their surroundings. That’s why they’re increasingly seen not just as transport units, but as intelligent mobility platforms capable of real time decision making and coordination.

What’s more, the software responsible for navigation and decision making is now continuously updated, enabling the robot to use past experiences as learning data. In simpler terms, this means the robot is evolving from something that merely moves on its own to a system that can learn from experience and make progressively better decisions over time.

2. Someone Leaves, but the Role Remains Filled

The growing interest in autonomous driving robots across today’s industrial settings isn’t just because they’re new or innovative. A more fundamental reason is the steady decline in the working age population, making it increasingly difficult especially in manufacturing and logistics to secure skilled labor reliably. In this context, maintaining simple, repetitive tasks or work in hazardous environments has become more challenging, and companies are actively searching for alternatives. One such alternative is the autonomous driving robot introduced here.

What makes this shift especially significant is that these robots are starting to acquire the ability to learn and improve over time. With each experience, they can fine tune their next actions and, when faced with unfamiliar situations, develop new responses independently. This evolution is not simply a matter of better hardware or faster processing it reflects a genuine ability to adapt to real world environments.

Previously, programming a robot required manually coding every detail of its behavior. A human had to specify how the machine should respond to every possible condition, which naturally limited the robot’s ability to operate in dynamic or unpredictable settings.

Now, however, the introduction of machine learning and generative AI is changing how robots are trained. In some experimental and research environments, robots can already interpret natural language instructions and translate them into appropriate actions. Though such capabilities are still limited in commercial settings, they demonstrate a major shift: from machines that follow fixed commands to systems that understand context and respond accordingly.

This trend lays the groundwork not only for improved task efficiency, but also for wider deployment of autonomous driving robots across various industries. As these technologies mature, the robots we once treated as simple tools may soon take on far more adaptive and collaborative roles in the workplace.

3. Application Areas

Autonomous driving robots are already playing a practical role across a wide range of industries, and their use is continuing to expand. They are especially effective in environments where human labor is limited or where tasks require high levels of repetition and consistency.

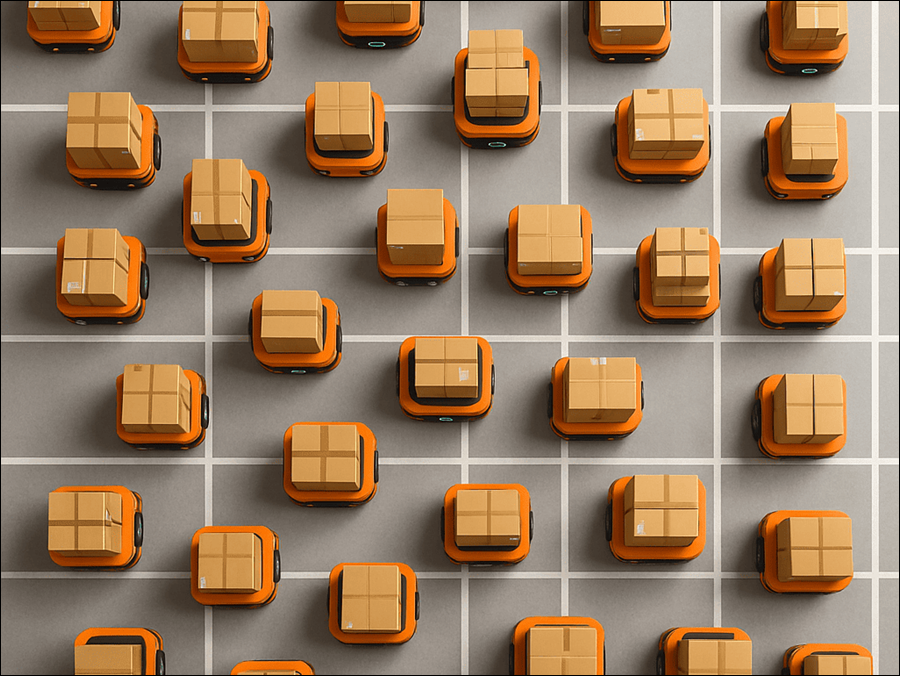

One of the most representative application areas is the logistics industry. The loading and transportation of goods has long been a key target for automation, and today, it serves as one of the most prominent sectors actively deploying autonomous driving technology.

Robots based on AGV (Automated Guided Vehicles) or AMR (Autonomous Mobile Robots) are now commonly used in warehouses, moving between shelving units while optimizing routes in real time. These systems can adjust their speed and direction based on surrounding conditions, enabling more efficient material handling. Companies like Amazon and Coupang have embraced this technology to automate large scale logistics operations.

Autonomous robots are also being introduced into service oriented environments such as hotels and shopping malls, where human foot traffic is high. These robots assist with a variety of tasks from greeting guests and guiding them through facilities, to delivering items directly to rooms.

In locations that operate 24 hours a day, these robots offer a significant advantage: they can continue working even when humans need rest, ensuring uninterrupted service. As a result, customers receive consistent service quality at all times, while operators benefit from improved labor efficiency and resource allocation.

4. Core Technologies

At first glance, an autonomous driving robot may not look very different from a conventional mobile robot. However, beneath the surface lies a complex system of advanced technologies intricately integrated to work as one.

These core technologies enable the robot to perceive its surroundings, make informed decisions, and carry out physical actions forming the complete operational cycle that defines true autonomy.

1) Sensors

Sensors allow the robot to perceive and understand its environment. They provide essential data for detecting obstacles and interpreting surrounding conditions. In fact, the reason autonomous driving robots can navigate routes and avoid collisions is largely thanks to these “eyes” of the system.

For example, LiDAR plays a critical role in helping the robot understand its surroundings. By emitting small laser pulses in multiple directions and measuring the time it takes for those pulses to bounce back, LiDAR enables the robot to create a detailed 3D map of the environment.

Even in narrow hallways or cluttered areas, this sensor allows the robot to judge where it can safely move and what to avoid.

Thanks to such sensor technology, autonomous robots aren’t just machines that move they are systems capable of real time environmental awareness and autonomous decision making.

2) Actuators

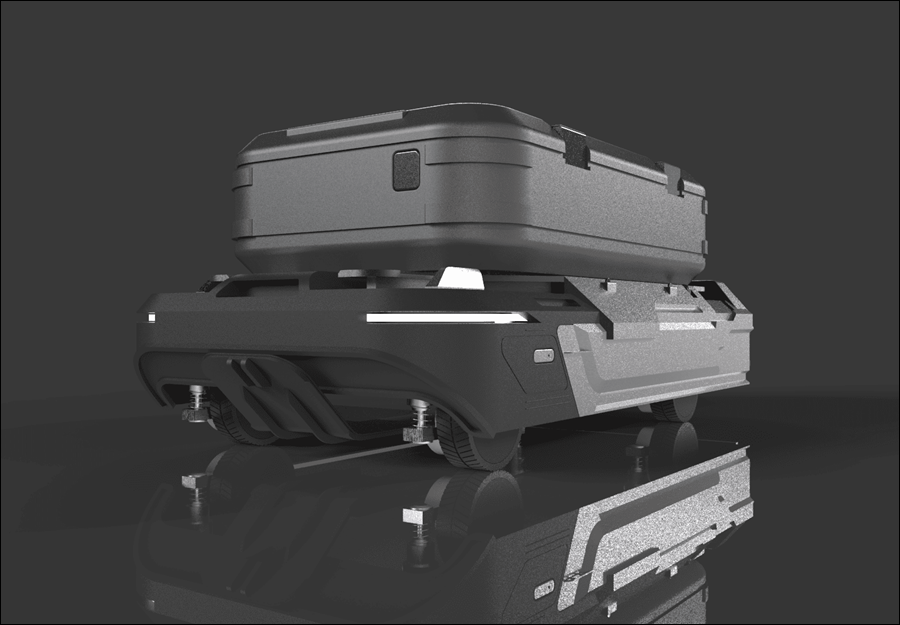

Once the robot has perceived its surroundings and determined what actions to take, it still needs a way to carry out those decisions. That’s where actuators come in.

Actuators are responsible for converting decisions into movement turning wheels, lifting arms, or carrying and placing objects. In simple terms, actuators give the robot the physical ability to perform the tasks it has chosen to do.

For instance, if a warehouse robot decides to transport a box, it’s the actuator that moves the robot toward the box, picks it up, and places it in the designated location. No matter how advanced the robot’s decision making system is, it would be ineffective without actuators that can reliably and precisely carry out those actions.

This is especially important in industrial settings where robots must handle heavy or delicate objects. The actuator must be powerful enough to lift substantial loads, yet precise enough to perform fine movements. Its performance directly affects the robot’s ability to operate in real world environments.

3) Control System

In order for a robot to perceive its surroundings and then decide what action to take, it needs a component that interprets and organizes the information this is the role of the control system. Often referred to as the robot’s “brain,” the control system receives a variety of data from the sensors, processes it in real time, and then determines the most appropriate action to take. It sends these instructions to the actuators to carry them out.

For example, imagine a robot is moving forward and suddenly encounters a person. It must decide whether to stop or change direction to avoid a collision. That decision is made by the control system, which also sends the signal to stop the wheels or steer the robot accordingly.

In a simple environment, this decision making process is relatively straightforward. But in a complex or unpredictable setting, the situation becomes far more challenging. Unexpected obstacles, unfamiliar objects, or rapidly changing surroundings require the control system to respond quickly and accurately, often recalculating the robot’s path in real time. The speed and accuracy of these decisions directly influence the overall performance and safety of the robot.

4) Machine Learning and AI

The evolution of autonomous driving technology from following fixed paths to making decisions based on real world conditions has been made possible largely through machine learning and artificial intelligence (AI).

In the past, every movement and condition had to be explicitly programmed by a human. Even slight changes in the environment required manual code adjustments, which made robots inflexible in dynamic settings.

Today, however, advances in AI are enabling some robots to adapt their actions using data from past experiences, gradually allowing them to make better decisions over time.

For instance, if an obstacle appears along a planned route, the robot no longer simply stops or reroutes in a fixed way. It can analyze the situation in real time, recalculate its path, or adjust its speed and direction based on environmental input.

This shift marks a clear difference from older systems that only repeated preset commands it reflects a move toward robots that can actively respond to changing conditions.

5. The Difference Between AGV and AMR

As autonomous driving technology becomes more common in industrial settings, the terms AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) are frequently mentioned. Both are mobile robots used to transport materials, but they differ significantly in how they operate and how much autonomy they possess.

An AGV follows a predefined route. It typically moves along magnetic strips or tracks installed on the floor, guiding it through fixed paths. This approach works well in stable environments where the layout rarely changes and repetitive tasks are common.

However, AGVs lack the ability to recognize or respond to unexpected changes in their environment. If an obstacle suddenly appears in their path, they usually stop and require human intervention. Deploying AGVs in a new work area often requires modifying floor infrastructure, which limits their flexibility in dynamic operations.

In contrast, an AMR is designed with the ability to perceive its surroundings and make decisions in real time. Using sensors, cameras, and mapping technologies, an AMR can determine its exact position and calculate the most efficient path to its destination avoiding obstacles and people along the way. There’s no need to install floor guides, and even if the environment changes, the AMR can adapt without manual reconfiguration.

To illustrate the difference: an AGV is like a train running on tracks it can only go where the tracks lead. An AMR, on the other hand, is more like a car using GPS navigation it can adjust its route depending on traffic or road conditions.

AGVs are predictable and stable, but limited in flexibility. AMRs are more adaptive and better suited for complex, shared environments.

In simple, unchanging settings, AGVs can still be an effective solution. But in dynamic workplaces where people and machines interact, AMRs provide a more practical and efficient alternative due to their ability to make decisions and respond autonomously.

6. The Era of Thinking Robots

Autonomous driving robots are no longer limited to simple, repetitive material transport tasks they are now evolving to handle heavy duty operations involving large and bulky cargo.

One of the most notable advancements is the development of high torque drive systems, which combine powerful force with stable movement.

This growing demand is closely tied to the rapid expansion of automation systems across various industries. In sectors such as port logistics, manufacturing, and construction where heavy materials must be moved repeatedly businesses have traditionally relied on large scale equipment like forklifts and cranes.

Today, however, the emergence of autonomous robots capable of transporting heavy cargo safely and efficiently is significantly increasing the feasibility of robotic deployment in such environments. A prime example is Hyundai Rotem’s recent contract for an 82.8 billion KRW unmanned transport system at Gwangyang Port, signaling a broader shift toward autonomous delivery platforms in the port logistics sector.

A similar transformation is occurring in manufacturing. As more operations require precise placement of heavy components such as machinery parts, vehicle frames, or metal structures, AGV based automation systems are gaining attention as a practical alternative. These systems offer superior space efficiency, repeatability, and safety compared to traditional manually operated equipment.

Another important trend is the adoption of Digital Twin technology. By creating virtual replicas of robots and their working environments, engineers can simulate robot movements and operations before deployment. This allows for early detection of potential problems, the design of optimal paths, and the prevention of collisions with existing infrastructure.

Together, these developments point to a clear direction. Autonomous driving robots are becoming more reliable, adaptable, and truly aligned with real world industrial needs. This marks a shift not just in technology sophistication, but in practical, scalable usability across complex environments.

7. No Longer a Technology of the Future

Autonomous driving robots are no longer a vision of the distant future. They are already being used in real world industrial environments, and their role is steadily expanding. More than just a technological innovation, these robots are taking on tasks traditionally performed by humans but in smarter, safer, and more efficient ways.

Of course, such changes may feel unfamiliar at first. But it’s important to view robots not as competitors threatening human jobs, but as collaborators that help create safer and more sustainable workplaces. By assigning robots to tasks that are repetitive, physically demanding, or potentially hazardous, we enable people to focus on more strategic and value driven roles within the organization.

The future of industry lies in collaboration between human judgment and robotic execution. We’re not entering a world where machines replace everything—but rather, a world where humans and machines work side by side, each contributing their strengths to create a more productive and balanced environment.

Bon Systems provides consultation and custom hardware solutions for autonomous driving robots, including reducers and actuators tailored to your operational needs. If you’re looking for technologies that align with your unique environment and goals, we invite you to contact us. For product inquiries or estimates, please visit our official website.