Table of Contents

In this article we will explore the differences between a Single Encoder and a Dual Encoder. The rapid progress of artificial intelligence is reshaping industrial environments at an incredible pace. From Tesla and Google to OpenAI, global tech giants are increasingly focusing on robotics as a central pillar of future industries. As a result, it has become common to encounter examples of AI powered robots being applied in real world factories and logistics systems.

When people think of this transformation, most immediately associate it with AI or Artificial Intelligence. However, this time we will take a slightly different perspective. Instead of beginning with algorithms and data, we will look at the physical foundation of robotics which is built upon actuators and sensors.

What is an Encoder and Why is it Important

A robot moves through a series of components such as reducers, mechanisms, and joints. Along the way, it faces issues like backlash in gears, elastic deformation, and frictional loss. These problems may seem small, but in collaborative robots, humanoids, or surgical robots designed for medical use, even the slightest error can lead to critical consequences.

In recent years, two approaches have gained attention. One is the development of high performance actuators that minimize error, and the other is the application of AI learning techniques that use accumulated data to correct deviations. Yet no matter how advanced the brain of a robot may be, meaning its AI, the absence of a physical body would always limit its ability to act. This is where actuators and sensors, especially encoders, become essential. They serve as the body and senses of the robot, connecting learned results to actual movement in the physical world.

An encoder is a key sensor in a robot control system that provides feedback on position, speed, and direction. If the controller acts as the brain by sending commands, and the driver works as the executor that powers the motor, the encoder is the sense organ that confirms whether the movement is taking place as instructed. For example, if the controller commands the motor to rotate ten turns, the driver delivers electrical energy to make that happen. In reality, due to backlash in the reducer, structural deformation, or friction, the end effector might only move about nine point eight turns. Measuring that difference and feeding it back to the controller for correction is precisely the role of the encoder.

The importance of the encoder can be summarized in two ways. First, it allows the end effector of a robot to reach the intended position with accuracy. Second, it supplies the data needed for AI to learn and improve precision by correcting errors over time.

Consider one example. Imagine a robot assembling electronic parts next to a human operator. The controller instructs the robot arm to place a screw in a designated position, and the driver activates the motor to move the arm. Yet because of slight play in the reducer or deformation in the mechanism, the end effector may arrive just off the target. With the encoder measuring the actual position and speed in real time and reporting back to the controller, the robot can immediately correct the error and insert the screw exactly where it is needed. Over time, the data accumulated through these repeated corrections can be used by AI to refine the process, making the robot faster and more precise with each cycle.

However, one condition must be met to enable this level of control. The system needs measurement values from both the input shaft and the output shaft in order to detect and correct errors accurately.

Single Encoder and Dual Encoder

A Single Encoder is usually mounted on the output side and provides the final value that reflects how much movement has occurred in response to a given command. In contrast, a Dual Encoder places sensors on both the input shaft and the output shaft.

This arrangement allows the system to compare how much the motor has actually rotated with the position reached by the end effector. By doing so, it becomes possible to identify the source of any error and to provide the data needed to correct the difference. As explained earlier, when a robot is expected to repeat tasks while maintaining high precision, a single feedback path often reaches its limits. This is why Dual Encoder systems, which capture information at both the input and output, are necessary.

Feedback in this context refers to the process of measuring the actual output of the system, comparing it with the target command, and using that difference to adjust the system’s operation. It is the information loop that enables correction and continuous alignment between intention and execution.

To make this easier to picture, imagine the controller of a robot acting as the brain. It sends a command to the motor, telling it to rotate ten turns, much like a person thinking about moving an arm. The driver, which functions as the executor, then says to the motor, I will supply the right amount of power so you can rotate ten turns. The motor receives that power and begins to spin, transmitting its motion through a reducer to move the robot’s arm.

The question arises, how do we know that the motor truly moved as commanded. This is where the encoder comes in. Acting as the eyes of the system, it measures in real time how the motor is moving. It reports back constantly with information such as how many turns are in progress, in which direction, and at what speed, allowing the robot to follow the command accurately. This describes the operation of a Single Encoder.

A Dual Encoder adds another layer by including a sensor on the output side as well. This makes it possible to compare the commanded movement with the actual outcome directly and to quantify any gap between the two. It is like having two observers watching the same task from different points of view, providing more precise information. The system can then use this error value to correct the position and speed of the end effector.

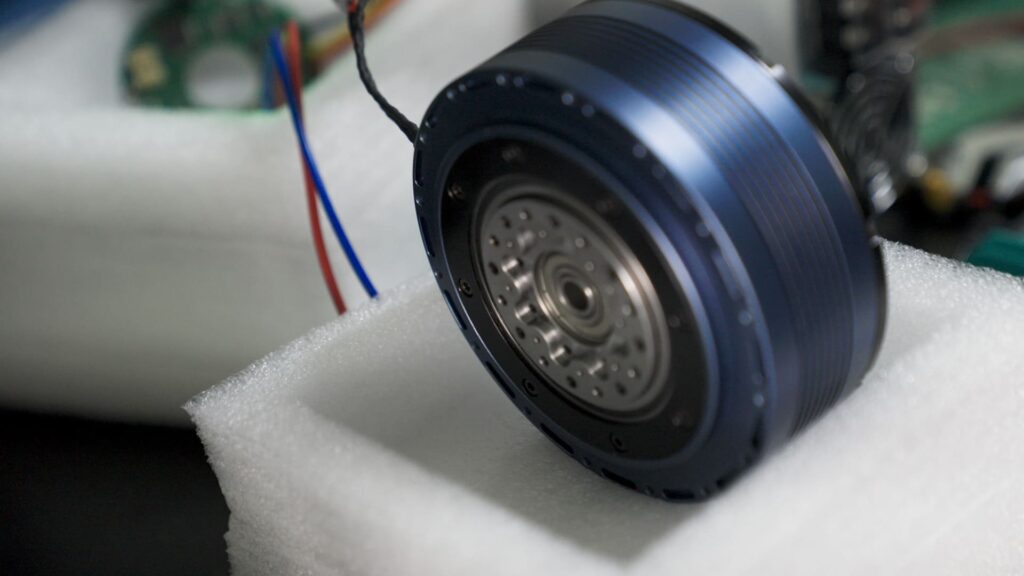

This is why a rising technology trend today is the smart actuator. Among its key components is the encoder, and depending on the design, products are offered in both Single Encoder and Dual Encoder versions. The terminology itself is not yet standardized, so the way it is labeled may vary across different companies.

What is a Smart Actuator

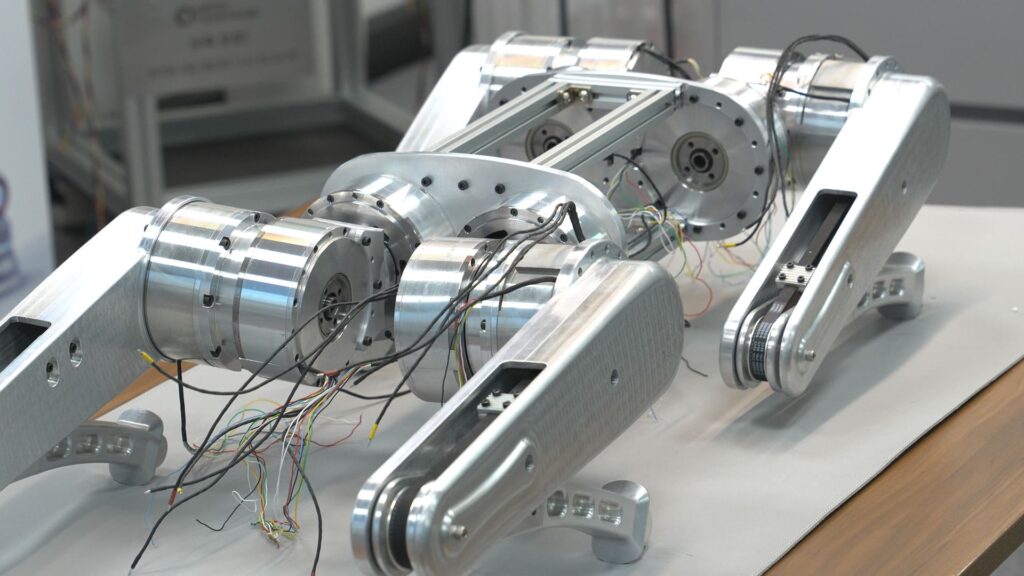

A smart actuator is an integrated drive module that combines all of the key components needed for robotic motion, including a reducer, motor, driver, encoder, and brake, into a single unit. From the perspective of an engineer, using such a unified component with built in control functions provides many benefits. It simplifies the design process, improves assembly efficiency, and makes maintenance more convenient.

This becomes especially important in intelligent robots such as humanoids, where every joint requires an actuator. For these systems, the integration of the control unit within the actuator is essential, as it makes wiring and component placement far easier. Most smart actuators currently available for robots are designed with a hollow shaft structure. This design allows wiring to pass through the input and output sections, greatly simplifying electrical connections.

The growing attention toward modular smart actuators is closely tied to the rise of humanoid robots, a market that is rapidly expanding alongside advances in AI. In these human like machines, the joints must meet several demanding requirements. They need to be lightweight, compact in form, and deliver high torque density all at once. Smart actuators are gaining traction because they provide an effective solution to these combined challenges.

Product Recommendation

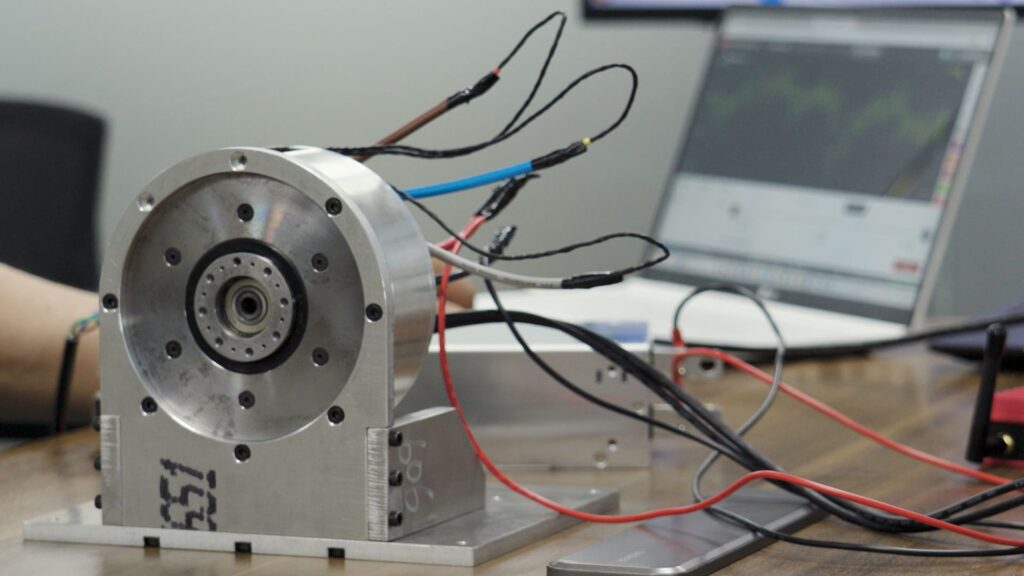

The key factor that defines the performance of a robot is the actuator that drives its joints. It is more than just a moving component, since the stability of power transmission and the level of design flexibility it enables often determine the success or failure of robot development. From this perspective, BCSA V4 is a product that engineers and researchers should pay close attention to.

This robotic actuator integrates the reducer, motor, and control driver into a single module and is built on cycloidal reduction technology. It delivers high torque density and exceptional durability, producing powerful torque even within a slim profile. At the same time, its structure separates the reducer from the motor, making maintenance straightforward. The inclusion of a hollow shaft design further improves efficiency by simplifying wiring tasks.

The next generation smart actuator BCSA V4 is not limited to standard specifications and can also be customized to meet diverse requirements. It can be applied to humanoids, autonomous mobile robots, logistics robots, and many other fields. By reducing the weight of the joints while maintaining compact design and strong output, it becomes an ideal choice for projects that seek both lightweight construction and high performance. Thanks to its modular structure, assembly and maintenance are simple, allowing research and development efficiency to increase significantly.

Frequently Asked Questions (FAQ)

Q. What is an encoder

An encoder is a core sensor that measures the position, speed, and direction of a robot and provides feedback to the control system. Its role is to confirm whether the command given by the controller is being carried out accurately, and it helps correct errors in real time. The encoder is the foundation that enables a robot to reach the intended position and perform precise tasks.

Q. What is the difference between a Single Encoder and a Dual Encoder

A Single Encoder is usually mounted on the output side to check the final movement, providing basic position and speed feedback. A Dual Encoder, on the other hand, is installed on both the input shaft and the output shaft, allowing comparison between the actual motor rotation and the result at the end effector. This approach identifies the cause of errors more precisely and provides correction data, making it well suited for high precision operations or repetitive industrial robots.

Q. What is a smart actuator

A smart actuator is an integrated drive module that combines a reducer, motor, driver, encoder, and brake into one unit. Because it includes control functions, it offers several advantages such as simplified design, easier assembly, and more convenient maintenance. In robots like humanoids, where every joint requires an actuator, smart actuators are essential for efficient wiring and component arrangement.

Q. Why are encoders important in AI robots

AI powered robots are expected to go beyond simple motion and perform delicate tasks such as collaboration with humans, medical procedures, or precision assembly. In these cases, even a small error can cause serious problems. Encoders provide real time data that detects and corrects errors during operation. Furthermore, with accumulated data, AI can learn and improve, enabling the robot to perform tasks faster and more accurately over time.

Q. Where can I purchase BCSA V4

BCSA V4 is the next generation smart actuator developed and supplied by Bonsystems. It is built on cycloidal reduction technology, featuring high torque, strong durability, and a hollow shaft design. Customized production is also supported to meet specific requirements. For purchases and inquiries, you can contact Bonsystems through the company website. If you provide details about the intended use and required specifications, the consultation process will be quicker and more accurate.