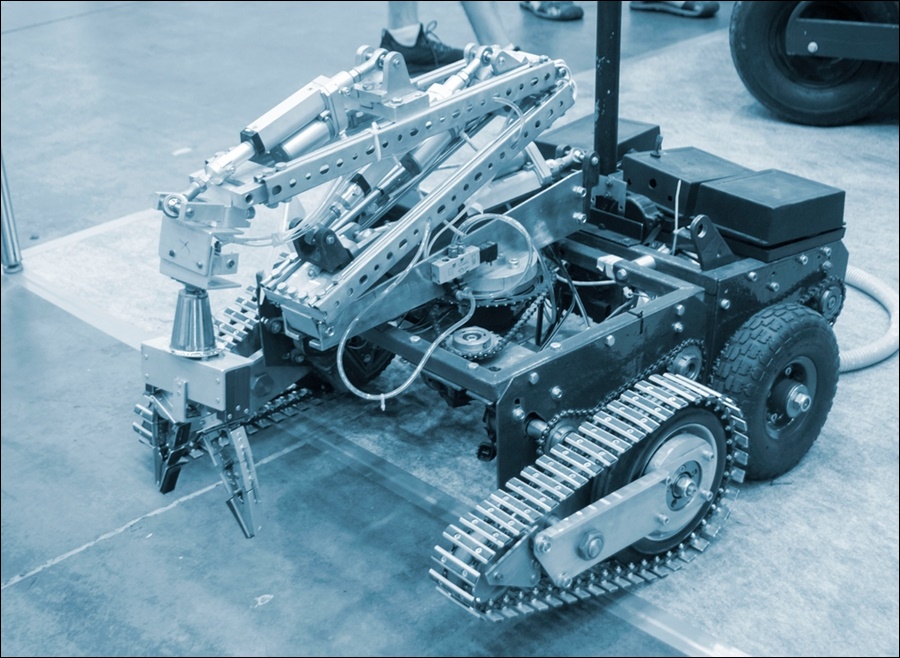

In this article, we will discuss the robot hardware industry. The speed at which AI technology is advancing is beyond imagination. From language and image processing to path planning, algorithms are becoming increasingly sophisticated. In industrial settings, AI is no longer just experimental it is now a practical, deployed technology.

However, there’s one crucial fact we must not overlook. No matter how advanced AI becomes, nothing happens in the real world unless the robot hardware can support and execute it.

Customizing Demand – A Matter of Survival, Not Choice

In the course of real-world projects, engineers often hear a familiar line: “It’s hard to meet our specs with off-the-shelf components.” If AI is the brain, then batteries, gear reducers, motors, and circuits form the essential body of a robot. However, during actual product development, teams frequently encounter various constraints in implementing robot hardware. Installation space may be limited, or the required torque and reduction ratio may not align with standard parts or existing designs.

For example, the drive modules of AGVs (Automated Guided Vehicles) are typically installed in narrow spaces underneath the machine. Within this restricted area, they must still generate enough torque to support loads from several hundred kilograms to even tons. At this stage, engineers must consider a range of specifications such as gear ratio, output torque, backdrivability, total volume and thickness, and input shaft diameter. In addition, the way the reducer connects to the motor and how it is mounted must flexibly adapt to the internal layout and system conditions. If these elements aren’t balanced properly, the overall design may be negatively affected.

For collaborative robots, position accuracy during repetitive motion and energy efficiency are key performance factors. In multi-joint structures, each axis movement is closely interlinked, so the backlash (gear play) and dynamic response of the reducer directly affect the robot’s overall control performance. In environments requiring high-precision control, even slight positional errors or uneven motion responses can degrade task quality. Accurate torque transmission and structural stability are critical requirements in robot hardware design.

The specifications of a reducer depend on the robot’s intended use, installation conditions, operating environment, control method, and target performance. It is rarely feasible for a single off-the-shelf product to meet all these requirements. When multiple conditions must be satisfied simultaneously, conflicts between specifications or functional compromises are often unavoidable. To overcome these constraints, a customized reducer designed from the beginning to match the project conditions becomes essential.

This is not just about increasing torque or speed. A successful hardware design must comprehensively consider available space, operating conditions, intended purpose, and compatibility with the motor. In actual projects, even a single reducer or actuator can directly influence the final product’s quality. In this context, having access to customizable drive components is not just an option but a key indicator of technological competitiveness.

The Reality of Limited Options

Most gear reducers available on the market today are built around standard specifications that prioritize general-purpose applications and mass-market demand. While this structure offers efficient choices for typical industrial settings, it can feel quite limiting when it comes to designs that involve special requirements or space constraints. Since few manufacturers provide flexible support for customization tailored to each project, it is not uncommon to struggle when trying to find a product that precisely meets the intended design specifications.

When a standard gear reducer is used as-is, discrepancies can arise between the design parameters set during the early stages of the project and the actual hardware performance during implementation. This mismatch may prevent the system from achieving the intended payload capacity and mobility, forcing engineers to alter or compromise the overall structure to fit the reducer’s limitations.

Consider a situation where a team is designing an autonomous mobile robot for a logistics automation environment. From the initial planning stage, the development team carefully defines the entire structure of the robot, taking into account fixed height, compatible motor size, required torque range, and expected travel speed. However, once the reducer selection process begins, it is common to encounter various constraints that hinder system integration.

Some reducers may meet the size requirements but fail to deliver the necessary torque. Others may provide sufficient torque output but exceed spatial limitations, especially in height, which forces revisions to the robot’s overall layout. When the design must conform to the constraints of the reducer, engineers lose their design flexibility and are pushed into unnecessary structural changes or performance compromises.

As a result, system optimization becomes more difficult, and the project faces unavoidable challenges such as additional machining, repeated redesigns, and performance trade-offs. These issues lead to schedule delays and rising costs. This clearly shows that the issue goes beyond simple product selection. It highlights why customized gear reducer design is a strategically important factor. In structures with severe spatial limitations, mismatched reducer specifications can easily become the root cause of mechanical interference and integration issues across the entire system.

How Custom Gearboxes Are Applied in the Field

Finding components that fully match design requirements is rarely easy. In many robot development projects, off-the-shelf gear reducers are used by default. This often forces teams to adjust their mechanical structures to fit the reducer or accept compromises in functionality. These choices typically result in delayed development schedules, increased costs, and reduced performance. This is not an isolated issue limited to special cases.

The demand for customization in gear reducers and robot hardware is growing across a wide range of industries. To secure both design flexibility and product performance, it is necessary to approach the initial design phase with the ability to adapt the gearbox structure to project-specific conditions. One example is a custom reducer developed for an AGV used in logistics automation.

The key challenge in this project was to secure enough output torque within a confined installation space while minimizing the overall system height. Standard reducers could not meet the dimensional constraints, so a new gear reducer integrated with the motor was custom-designed.

As a result, the team succeeded in reducing the thickness of the gearbox by approximately 70 percent compared to conventional products. This improvement enhanced space efficiency and simplified assembly. This was not a simple case of adjusting dimensions, but a clear example of structurally optimizing the reducer to meet real-world project conditions. In low-profile systems like AGVs, it is crucial to plan for customized gearboxes from the early stages. Doing so allows teams to preserve design freedom, avoid unnecessary structural revisions, and achieve both performance and efficiency in robot hardware systems.

Customized Gear Reducer Solutions

Bonsystems has developed a field-oriented design process for custom gear reducers, actuators, and robot hardware based on data collected through a wide range of robotics projects. With a focus on high-torque, thin-profile cycloidal reduction technology, we have built design capabilities that meet diverse physical requirements across various industrial environments.

Our custom manufacturing solutions are not simple modifications of existing products. We define the hardware from scratch to suit the specific needs of each customer project. For example, in systems like AGVs and AMRs where load transport is critical, thin designs that still deliver high torque are essential. In contrast, for collaborative robots or 6-axis robots where repeatable precision is the priority, lightweight construction and highly responsive, efficient control are key.

To support productivity through accurate repetition, we offer low-backlash mechanisms and hollow shaft designs that simplify complex wiring. Every element can be tailored to the customer’s requirements, including torque range, reduction ratio, output direction, motor compatibility, and installation constraints.

For effective consultation and rapid response, it is helpful to share key project details when making an inquiry or requesting a quote. These include intended use, mounting location, required torque and reduction ratio, motor specifications, and estimated delivery time. Providing layout drawings or specifications of previously used parts also enables faster analysis and configuration. All technical consultations are free of charge, and we offer one-on-one customized specifications when conditions are clearly defined.

As robots become more intelligent, their hardware must become more flexible and precise. If AI is the brain, gear reducers and actuators are the joints that enable motion. The era of assembling pre-defined parts is over. Today, hardware must be designed from the beginning to match the robot’s specific goals. The role and importance of robot hardware will only continue to grow. Bonsystems stands as a trusted technical partner, offering custom hardware solutions that go beyond the limits of off-the-shelf components. Start your design process with us today and bring your robotic systems to life with precision and purpose.