Table of Contents

When designing a robot, the first crucial step is to determine how much force is needed to perform a given task. Once the required force level is identified, the next step is to figure out how to combine a motor and a gearbox to generate that force in a stable and controlled manner. The key concept at this stage is torque. A gearbox reduces the rotational speed of the motor while simultaneously amplifying the torque. In this article, we’ll take a closer look at how motors and gearboxes are paired together, and how torque is calculated in that system.

What is a motor gearbox?

A gearbox is a mechanical device that reduces the rotational speed generated by a motor. Motors typically operate at high speeds with relatively low output torque, making it difficult to directly use them for applications that require controlled movement or higher force. A gearbox addresses this by lowering the motor’s rotational speed while proportionally increasing the torque according to the gear ratio.

For example, if a motor rotates at 3,000 rpm and is connected to a gearbox with a 30:1 reduction ratio, the output shaft will rotate at 100 rpm, and the output torque will theoretically increase by a factor of 30. In this way, a gearbox allows high-speed motor output to be converted into a controllable level of speed and amplified force.

Thanks to these characteristics, gearboxes are essential in systems that require consistent force or repetitive motion. In automated equipment, they help move conveyor belts at a constant force; in logistics robots, they enable heavy lifting and movement; and in collaborative or multi-joint robotic arms, they ensure stable motion with consistent speed and precision.

The design and performance of a gearbox directly affect the overall system’s torque capacity, backlash, durability, and efficiency. Therefore, a gearbox is not just a speed-reducing component, but one of the most critical parts that define the performance of the entire drive system.

What is torque?

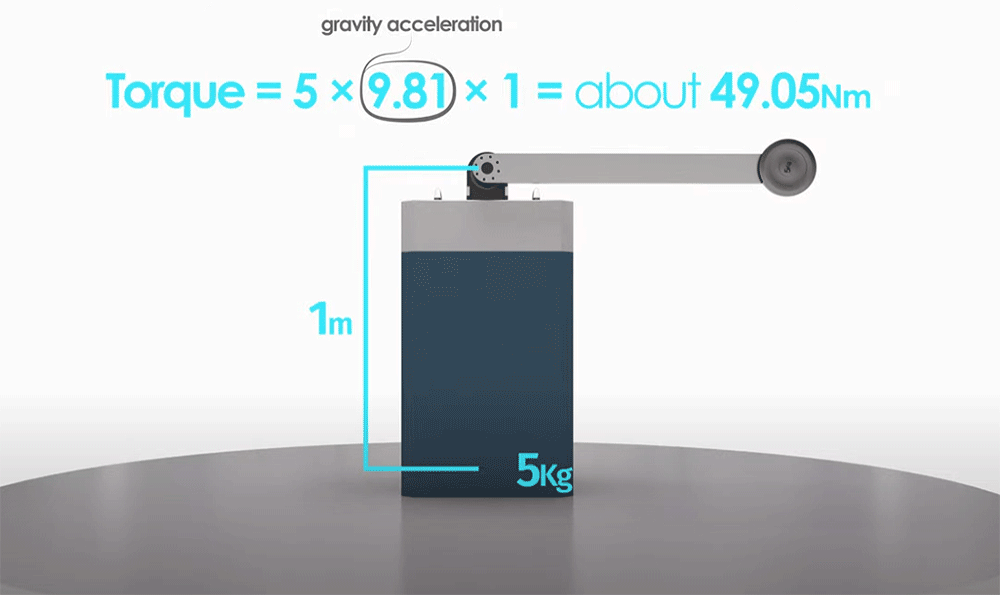

Torque refers to the rotational force applied to an object and is a fundamental concept in all mechanical systems involving rotational motion. It is typically measured in newton-meters (N·m). Torque takes into account not only the magnitude of the force but also the distance from the axis at which the force is applied. This means that even the same force can produce greater torque if applied farther from the center of rotation.

Motors are a primary source of rotational motion, and their performance is usually described in terms of torque and rotational speed (rpm). The torque mentioned in this context refers to the motor’s rated torque — the amount of force the motor can continuously provide under stable conditions. Most general-purpose motors are optimized for high-speed operation, which often results in relatively low rated torque. This makes it difficult to directly support heavy loads, creating the need for additional components that can increase torque.

This is where gearboxes come into play. A gearbox reduces the motor’s rotational speed and simultaneously increases the torque output. The output torque increases in proportion to the gear ratio. However, in real-world applications, factors such as internal friction, gear interference, and lubrication losses within the gearbox lead to energy loss. Therefore, when calculating torque, the efficiency of the gearbox must be taken into account. This efficiency is generally assumed to be in the range of 70 to 90 percent, and reflecting this is crucial to accurately estimating the actual output torque in operating conditions.

How to calculate torque in a motor-gearbox system

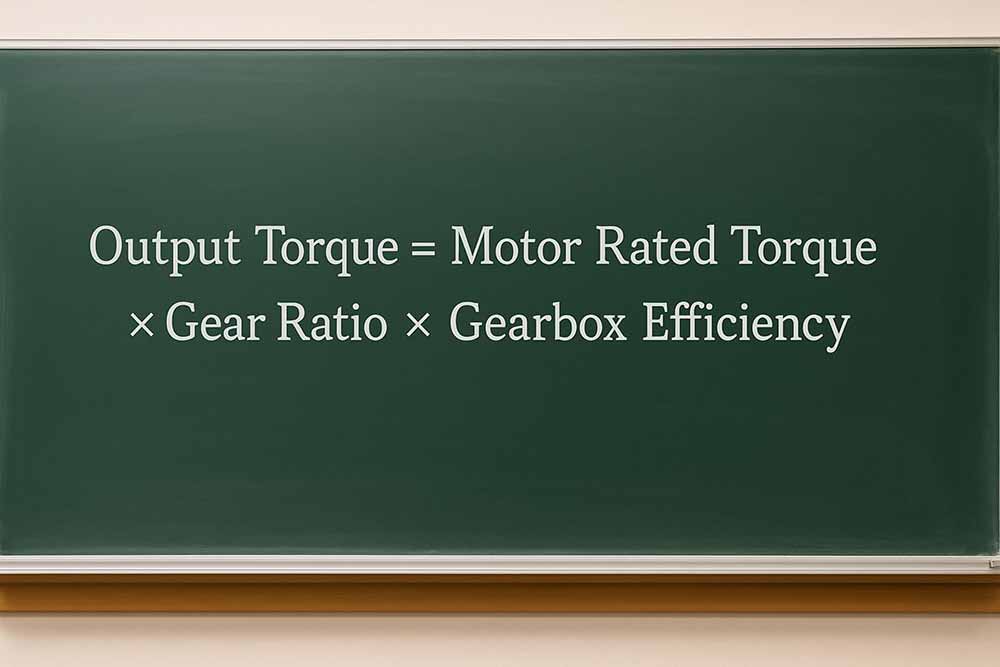

The output torque of a motor equipped with a gearbox can be calculated using the following formula.

Output Torque = Motor Rated Torque × Gear Ratio × Gearbox Efficiency

First, the motor’s rated torque refers to the rotational force the motor can generate continuously under optimal conditions without overheating. This value is typically specified in the motor’s datasheet and is determined based on factors such as voltage, current, and the motor’s internal design.

Next, the gear ratio represents the difference in rotational speed between the input shaft (motor) and the output shaft (gearbox). For example, with a gear ratio of 29:1, the motor must rotate 29 times for the gearbox’s output shaft to complete one rotation. A higher gear ratio reduces the output speed and proportionally increases the output torque.

Gearbox efficiency indicates how much of the motor’s input energy is actually transmitted to the output shaft. Since gearboxes include components such as gears, bearings, and lubrication systems, some energy loss due to friction and mechanical resistance is inevitable.

For instance, if a motor has a rated torque of 1.3 N·m, a gear ratio of 29:1, and a gearbox efficiency of 75%, the output torque is calculated as follows.

Output Torque = 1.3 × 29 × 0.75 ≈ 28.3 N·m

This value represents the continuous rotational force available at the gearbox’s output shaft and serves as a reference when designing mechanical systems. Selecting an appropriate combination of motor specifications and gear ratio according to the torque requirements is essential for ensuring optimal system performance.

Applying a Safety Factor

Theoretically calculated output torque serves only as a reference under ideal conditions. However, real-world operating environments are rarely stable. Sudden stops, external shocks, temperature fluctuations, and lubrication conditions can all cause the system to require greater torque than initially anticipated even if only momentarily.

To account for such uncertainties, it is standard practice to apply a Safety Factor when calculating torque. The safety factor introduces a margin of tolerance by designing for a higher torque than the calculated requirement. This helps ensure the system’s reliability and extends its operational lifespan.

For example, if the calculated output torque is 28.3 N·m and a safety factor of 1.5 is applied, the design torque becomes:

Design Torque = 28.3 N·m × 1.5 = approximately 42.5 N·m

The appropriate safety factor varies depending on the nature of the equipment, type of load (static or dynamic), operating time, motion frequency, and the required level of reliability. Typically, safety factors range between 1.2 and 2.0. Higher values are recommended for systems subject to frequent load cycles, repeated starts and stops, or environments with high variability.

By incorporating a safety factor during the design phase, you can select a motor and gearbox combination that ensures stable operation even under unexpected conditions.

Design Considerations

The design torque, calculated by applying a safety factor to the theoretical output torque, serves as a key reference when selecting a motor and gearbox. Based on this value, you should refer to the gearbox specification sheet and identify models whose allowable rated torque meets or exceeds the design requirement. If necessary, adjustments can be made by modifying the gear ratio or selecting a different motor to ensure the overall drive system is properly matched.

For instance, if the design torque is set at approximately 42.5 N·m, you must review potential combinations of motor and gearbox that satisfy this requirement while accounting for gear ratio and efficiency. While the previous example focused on torque alone for simplicity, real-world mechanical design involves evaluating several additional factors. These include rotational speed, durability, backlash, and resistance to backdriving.

A thorough evaluation of the gearbox’s structural characteristics in relation to the intended operating environment is essential. Selecting components based on this broader context will contribute to long-term system stability and operational reliability.

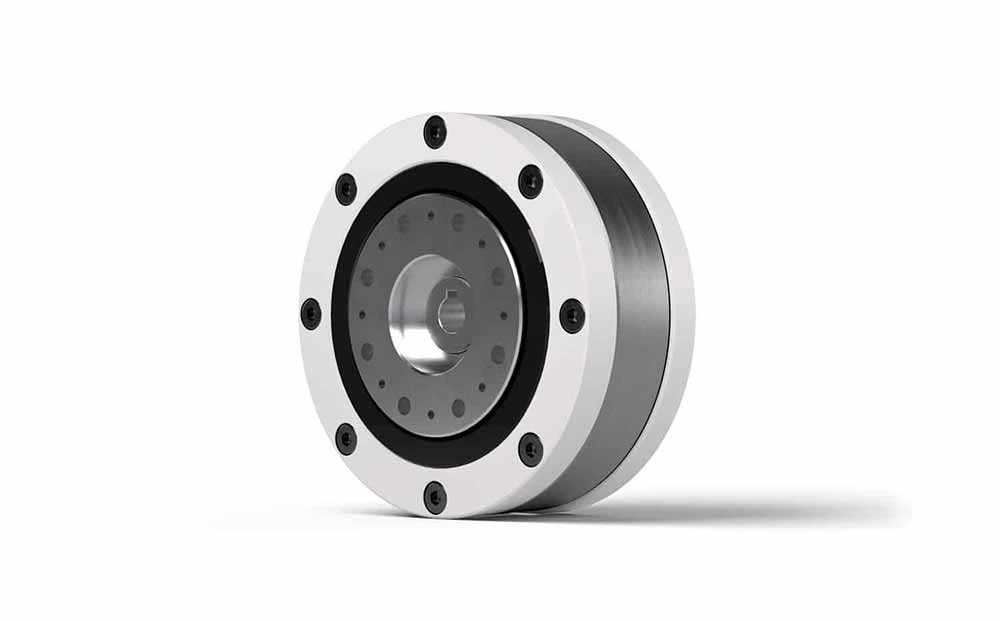

If you’re looking for a compact yet high-torque gearbox,

The BSR Series is an ideal solution for applications that demand high output torque. Based on a cycloidal gear structure, it offers backlash of less than 10 arcmin and maintains an efficiency level of approximately 75%.

Designed with a slim profile, the BSR Series is particularly well-suited for robot joints and installations with limited space. It supports multiple gear ratios within the same external form factor, allowing you to fine-tune performance requirements without changing the model.

This gearbox excels when both rated torque and compact dimensions are critical. Thanks to its flexible gear ratio options and adaptable assembly design, the BSR Series provides an effective solution during the component selection phase — once motor specifications and design torque targets have been determined.

FAQ

Q1. Does using a gearbox always increase torque?

Yes, using a gearbox increases the output torque in proportion to the gear ratio. However, the actual output torque must account for efficiency losses due to internal friction, lubrication, and mechanical resistance. Typically, gearbox efficiency ranges between 70% and 90%, and this must be factored into the final torque calculation.

Q2. Why does speed decrease as the gear ratio increases?

The gear ratio represents the relationship between the input shaft and the output shaft’s rotational speed. For example, a 30:1 gear ratio means the motor rotates 30 times for every 1 rotation of the output shaft. This results in the output shaft rotating 30 times slower than the input.

The speed reduction occurs because the internal gear mechanism distributes and converts the input motion through multiple stages. While speed decreases according to the gear ratio, this process allows for a proportional increase in torque.

Q3. Why should a safety factor be applied in torque calculations?

While theoretical torque is calculated under standard conditions, real-world machines experience variables such as sudden stops, repeated shocks, and fluctuating loads. A safety factor provides a margin of tolerance to account for these variations, helping to prevent overload and extending the system’s lifespan. It is a critical part of robust mechanical design.

Q4. Once the output torque is calculated, how is the gearbox selected?

Start by multiplying the calculated torque by a safety factor to obtain the design torque. Then, refer to gearbox specification sheets to find a model that can handle this torque or higher. Consider additional factors such as gearbox size, backlash, and installation constraints before making a final selection.

Q5. Besides output torque, what other factors are important when selecting a gearbox?

In addition to torque, factors such as backlash, durability, permissible moment load, shaft direction, efficiency, size, weight, and mounting style are critical. For systems involving frequent repetitive motion, it is especially important to evaluate both durability and torque capacity together.